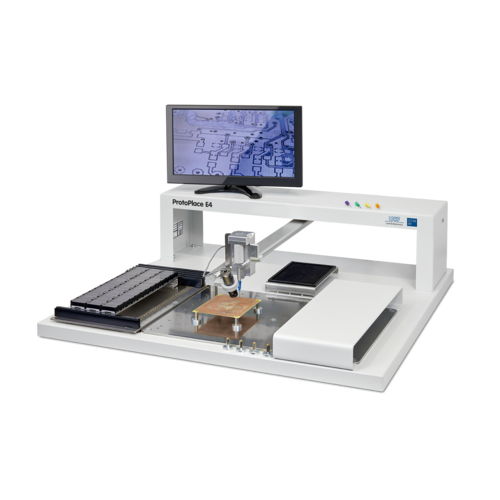

LPKF ProtoMat S64

The allrounder in printed circuit board processing

Suitable for almost all in-house prototyping applications

The milling spindle with 60 000 rpm guarantees shortest machining times and highest geometric accuracy. It is low-maintenance due to the new pneumatic self-cleaning function for milling spindle and milling depth sensor. The granite machine base also ensures consistently accurate results.

Up to 15 tools – more if required – can be changed automatically during the production process. Depending on the intrusion depth, the conical milling cutters generate different insulation channels. The automatic milling width adjustment ensures that the milling contour has a constant width. This shortens the set- up time and enables operator-free performance. Sensors in the ProtoMat S64 ensure optimally controlled, exact milling depth and also monitor the tool change process.

Εντός 10 ημερών / Up to 10 days

Categories: PCB MILLING MACHINES, PCB PROTOTYPING MACHINES, WELLER